Why FEP Insulated Oil-Resistant Cables Are the Gold Standard for Harsh Industrial Environments

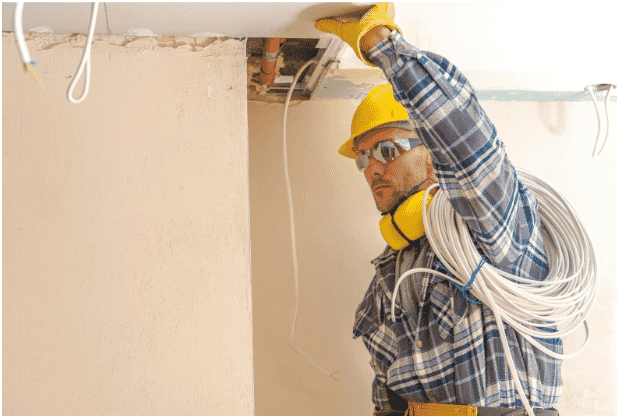

In demanding industrial environments like refineries, chemical plants, and manufacturing facilities, electrical cables are exposed to extreme conditions that can severely compromise their performance and longevity. These environments are often characterized by high heat levels, exposure to harsh chemicals, and contact with industrial oils. Under such conditions, standard cables can quickly degrade, leading to failures that can cause downtime, costly repairs, or even dangerous safety incidents.v

For these reasons, FEP insulated oil-resistant cables have emerged as the gold standard in harsh industrial environments. These cables can withstand the challenges posed by demanding settings. They offer unmatched durability, excellent resistance to chemicals and oils, and high thermal stability, making them a reliable solution for industries that cannot afford frequent cable failures.

We examine FEP cables' unique properties and explain why they are ideal for harsh industrial environments.

Understanding the Challenges in Industrial Environments

Industrial settings like chemical plants, oil refineries, and manufacturing facilities are notorious for their hostile conditions, where cables are exposed to a variety of environmental hazards:

Exposure to Oils and Chemicals

Cables are routinely exposed to oils, solvents, and corrosive chemicals in industries such as oil and gas or chemical processing. These substances can degrade cable insulation, leading to malfunctions, electrical failures, or even hazardous situations like fires. If cables aren't adequately protected, they can quickly break down, causing unplanned downtime and expensive repairs.

Extreme Temperatures

Many industrial processes generate high heat, which can significantly damage standard cables. High temperatures can melt or weaken the insulation, leading to short circuits and various electrical issues. In some industries, such as metal processing or power generation, the temperatures can exceed the capacity of traditional cable materials.

Mechanical Stress

Industrial environments are typically characterized by moving machinery, vibration, and mechanical abrasion. Cables in such settings must be highly flexible and withstand constant movement without breaking down. In some applications, cables may be pulled or stretched, leading to mechanical wear and tear over time.

Given these challenges, gas and oil-resistant cables made from FEP (fluorinated ethylene propylene) are a top choice for protecting electrical systems from these harsh conditions.

What Makes FEP Insulated Cables Stand Out?

FEP insulated oil-resistant cables offer several properties that make them ideally suited for the harsh conditions found in industrial settings.

Oil and Chemical Resistance

One of the primary benefits of FEP insulated oil-resistant cables is their exceptional resistance to industrial oils, solvents, and chemicals. In industries where cables are frequently exposed to aggressive chemicals, FEP insulation remains stable, providing a long-lasting barrier that prevents degradation. On the other hand, traditional materials like PVC often fail to withstand such exposure, leading to rapid deterioration and frequent replacement.

Heat Resistance

Heat-resistant FEP wire can endure extreme temperatures, making it suitable for environments where high heat is a factor. FEP insulation can withstand temperatures as high as 200°C without breaking down, delivering continuous performance even in the hottest environments. This makes FEP cables ideal for industries like manufacturing, oil and gas refining, and power generation, where heat levels can easily exceed the limits of other materials.

Durability in Dynamic Environments

FEP cables offer a unique combination of flexibility and toughness. In dynamic industrial settings where cables are subject to constant movement, bending, and vibration, FEP insulated oil-resistant cables maintain their structural integrity. This decreases the risk of mechanical failure and extends the service life of the cables, ultimately lowering maintenance costs and minimizing downtime.

Key Benefits of Using FEP Cables in Industrial Settings

FEP cables offer numerous advantages, making them the preferred choice in industrial applications. Below are the three key benefits that FEP insulated oil-resistant cables deliver.

Durability and Longevity

Durable gas and oil-resistant FEP cables are engineered to last. Compared to traditional materials like PVC, they are less prone to degradation from exposure to chemicals, oils, or extreme heat. This means fewer replacements and reduced maintenance costs over the long term. For industries that operate 24/7, having reliable cables is essential to avoiding costly production stoppages.

Improved Safety

In addition to their durability, FEP cables also provide superior safety features. Their high resistance to thermal degradation means they are less likely to fail due to overheating. Their chemical resistance ensures that they do not break down when exposed to corrosive substances. Maintaining their integrity over time, FEP cables help reduce the risk of fires, electrical shorts, and other safety hazards.

Reduced Maintenance and Downtime

By choosing high-performance FEP wiring solutions, industrial operations can minimize the frequency of cable replacements and the required maintenance. Fewer breakdowns translate to fewer interruptions, keeping operations efficient. Reducing maintenance costs and minimizing downtime can result in significant savings for industries with large-scale operations.

Comparing FEP Cables to Traditional Materials

In harsh industrial environments, it is important to understand why FEP cables outperform traditional materials like PVC, rubber, and other types of insulation. Below is a comparison that highlights the key differences.

Feature FEP Insulated Cables PVC Insulated Cables Oil Resistance Outstanding resistance to oils and solvents Moderate resistance, prone to degradation Chemical Resistance Exceptional resistance to chemicals Vulnerable to chemical attack Heat Resistance Withstands temperatures up to 200°C Limited to about 70-90°C Durability Highly durable in harsh environments Degrades faster in challenging conditions Maintenance Needs Minimal maintenance required Frequent maintenance due to rapid wear

Applications of FEP Insulated Oil-Resistant Cables

FEP insulated oil-resistant cables are used across various industries due to their unique properties. Some of the critical applications include:

Refineries

In oil refineries, where equipment is exposed to high temperatures and industrial oils, FEP cables offer the necessary durability and protection. These cables are often used in critical systems, such as control panels and power distribution systems, that must always remain operational.

Chemical Processing Plants

The risk of exposure to corrosive chemicals in chemical plants is high. Chemical-resistant FEP cables provide the necessary protection to keep electrical systems safe and continuously operating in these environments.

Manufacturing Facilities

In manufacturing facilities where machinery is constantly in motion, heat-resistant FEP wire provides reliable performance. These cables are often used in applications where heat and exposure to oils or chemicals are significant risks.

How to Select the Right FEP Cables for Your Needs

When selecting FEP insulated oil-resistant cables for industrial applications, it's essential to consider several factors:

Exposure to Chemicals and Oils: Evaluate the types of chemicals and oils the cables will be exposed to in your specific application.

Temperature Requirements:v Consider the temperature range your cables will need to withstand, both during normal operations and during potential extreme conditions.

Flexibility Needs: Ensure that the cables have the necessary flexibility for the application, especially if they will be used in dynamic environments with constant movement.

Compliance with Industry Standards: Check that the selected cables meet all relevant safety and performance standards, particularly for harsh environments.

After considering these factors, you can feel confident knowing that you are selecting the best high-performance FEP wiring solutions for your industrial operations.

Making The Most With FEP Insulated Oil-Resistant CablesMaking The Most With FEP Insulated Oil-Resistant Cables

FEP insulated oil-resistant cables provide unmatched performance in demanding industrial environments. Their exceptional resistance to chemicals, oils, and high temperatures offers long-term reliability and safety, reducing the need for maintenance and minimizing downtime. These cables are the gold standard for maintaining efficient operations and protecting critical systems in industries like refineries, chemical plants, and manufacturing facilities.

If you're looking for gas and oil-resistant cables that offer long-lasting durability and superior protection in harsh environments, our team at Windy City Wire can help. Visit our Resource Center or contact us today to learn more about our FEP insulated oil-resistant cables and how they can enhance the safety and efficiency of your industrial operations.