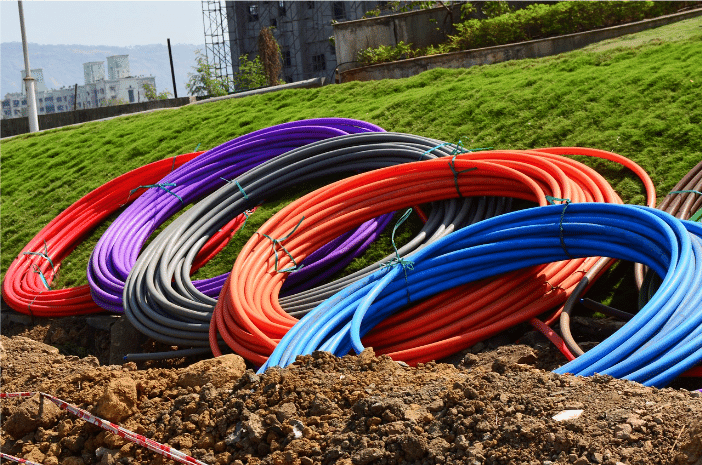

Understanding Direct Burial Cables for Underground Projects

Underground wires come into play across various industries, from construction to security systems. These wires (or cables, as the words are often interchangeable) can handle challenging conditions, making them essential for environments exposed to soil, moisture, and other harsh elements. Direct buried wire, direct burial electrical wire, and Ethernet underground cables are among the most commonly used types, as they maintain functionality and safety in demanding situations. We put together this guide to take a deeper look into the features and advantages of underground cables and explain why they are so crucial in specific environments.

What is Direct Burial Wire?

Direct burial wire is designed for direct installation in the ground without requiring additional protective conduit. Unlike standard cables that may not withstand underground environmental challenges, direct burial wire resists moisture, soil acidity, and physical damage. The cables feature multiple insulation layers and a rugged outer jacket that protects the inner conductors from external threats. These protective layers commonly use materials such as PVC (polyvinyl chloride), polyethylene, and other water-resistant compounds. This construction ensures the cable remains operational, even when exposed to moisture or fluctuating temperatures.

These wires are often utilized in commercial and industrial projects where safety and functionality are paramount. For instance, direct burial electrical wires are frequently employed to transmit power between buildings or power outdoor equipment. At the same time, Ethernet underground cables establish network connections between remote locations. Their design allows them to perform effectively in outdoor and underground environments where standard cables might fail.

Top Features of Direct Burial Electrical Wire

Direct burial electrical wires have several features that make them suitable for underground projects.

- Water Resistance: One of the primary concerns for underground cables is exposure to moisture. Direct burial electrical wires are equipped with water-resistant insulation that prevents water ingress, which could otherwise lead to electrical faults or corrosion.

- Temperature Tolerance: These cables can withstand a wide range of temperatures. Whether in cold climates or exposed to heat, direct buried wires maintain their structure and continue to function effectively.

- Extended Lifespan: Their protective coatings and robust materials give direct burial wires a longer lifespan than standard cables. They can endure the physical stress and environmental conditions found underground, which helps reduce maintenance needs and replacements over time.

- Variety for Specific Applications: Various direct burial electrical wires are suited for particular uses. Some are designed for high-voltage applications, while others are tailored for data transmission.

- Compliance with Industry Standards: It is crucial to choose direct burial wires that meet established safety and performance standards. These standards ensure that the cables are manufactured according to specific criteria, providing peace of mind for professionals who rely on them in critical applications.

Benefits and Uses of Ethernet Underground Cables

Ethernet underground cables are essential in modern network communications, mainly in outdoor or buried environments. These cables provide stable data transmission while protecting against environmental factors.

- Protection Against Environmental Factors: Ethernet underground cables come with protective jackets that shield them from moisture, UV rays, and physical damage. This protection allows the wires to maintain data transmission capabilities even in challenging environments.

- Maintaining Signal Integrity: Signal integrity is crucial in network communications. Ethernet underground cables are constructed with materials that minimize signal loss and interference, ensuring consistent data transmission over long distances.

- Long-Term Functionality: Ethernet underground cables offer a long service life due to their construction. They are less likely to experience failures caused by environmental stress, reducing the need for frequent replacements and upkeep.

- Broad Application Range: These cables are commonly used in outdoor networking, connecting security cameras in extensive outdoor areas, and establishing network connections between separate buildings. Their ability to perform well in varied conditions makes them versatile for many applications.

Why Choose Direct Burial and Underground Cables for Challenging Conditions?

Direct burial and underground cables perform well in challenging environments, making them the preferred choice for many applications. Their construction allows them to withstand physical and environmental stress, making them a cost-effective solution. These cables typically require less maintenance than their non-buried counterparts, as they are less exposed to potential damage from weather, animals, and other external threats.

Using direct burial and underground cables also minimizes downtime in critical systems. In industries where maintaining continuous operation is essential (think construction, security, or data management), these cables provide a solution that can handle the demands of the environment. Additionally, selecting the correct cable type for the application helps ensure compliance with safety regulations, reducing the risk of costly repairs or replacements.

Additional Considerations for Choosing Underground Cables

When selecting underground cables, consider factors such as soil conditions, potential exposure to chemicals, and the presence of pests. Certain soils may have corrosive properties that can affect cable materials over time, making it crucial to select cables with appropriate protective coatings. Similarly, areas with a high presence of rodents or insects may benefit from cables designed with additional protective layers to deter damage.

Another consideration is the potential for future upgrades or repairs. Cables that are easier to access or identify can simplify maintenance work. Invest in cables that support your current and future technological needs to reduce the need to replace underground cables too often.

Making Smart Decisions With Direct Burial Cables for Underground Projects

Selecting the best cable for underground projects helps maintain safety, functionality, and efficiency. Direct burial wires, direct burial electrical wires, and Ethernet underground cables offer practical solutions for harsh environments, minimizing maintenance needs and ensuring long-term performance.

Whether managing a large-scale construction project or setting up a secure outdoor network, choosing the suitable cable can significantly impact your project's success. We offer various options tailored to different industry needs, providing solutions that comply with industry standards and are built to last.

Understanding the features and benefits of direct burial and underground cables enables you to make educated decisions that enhance the safety and quality of your projects. For more information on selecting the perfect underground cable for your needs, explore our product offerings or contact us for information tailored to your specific requirements.